NBR

- Home

- Products

- NBR

- Hydraulic Rod Seals

- Hydraulic Piston Seals

- Hydraulic Wiper Seals

- Pneumatic Rod Seals

- Pnuematic Piston Seals

- Guiding Elements

- Static Sealing Elements

- Rotary Shaft Seals

- Axial Face Seals

- Bonded Seal

- End Cap Seal

- Mechanical Seals

- Single Spring Mechanical Seal

- Apv Pump Seal

- Famous Pump Seals

- Metal Bellows Seals

- Auto Cooling Pump Seal

- Flygt Pump Seal

- Inflatable Seals

Our Brochure

View our new brochure for an easy to read guide on all the products we offer.

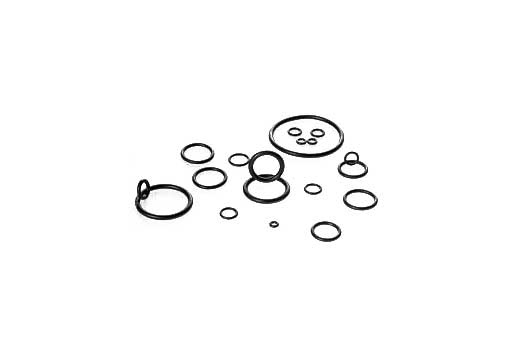

NBR

NBR

.

NBR

.

NITRILE RUBBER (NBR)

Nitrile rubber, also known as NBR or Buna N, is one of the most commonly used sealing elastomers due to its resistance to petroleum based fuels and lubricants and its relatively low price. Nitrile elastomers are copolymers of acrylonitrile and butadiene. There are a number of common variations of nitrile compounds.

ACRYLONITRILE CONTENT

The acrylonitrile (ACN) content of the polymer chains can be varied from 18% to 50%. Lower ACN content gives better low temperature properties but poorer fuels and polar lubricants. Higher ACN content gives poorer low temperature properties but improved fuels and polar lubricants resistance. Standard NBRs typically have 34% ACN content.

CURE SYSTEM – SULFUR-CURED VS. PEROXIDE-CURED

Standard Nitriles are usually sulfur-cured. Sulfur-cured compounds offer better low temperature properties but are more prone to hardening with high temperatures. Peroxide-cured nitriles have better heat resistance and lower compression sets but are more expensive and are more difficult to process.

OTHER COMMON VARIATIONS

Nitriles can be formulated with only “white list” ingredients as specified in 21.CFR 177.2600 for use in applications where the elastomer will be in contact with food or beverages.

Nitriles can be submitted for approval by the National Sanitation Foundation (NSF) for use in drinking water applications.

Nitriles can also be submitted for approval to Underwriters Laboratories (UL) for use in applications as prescribed in UL157.

Nitriles are often internally lubricated to improve ease of installation or reduce friction for dynamic applications.

GENERAL INFORMATION

- ASTM D 1418 Designation: NBR

- ISO/DIN 1629 Designation: NBR

- ASTM D2000 / SAE J 200 Codes: BF, BG, BK, CH

- Standard Color(s): Black

- Hardness Range: 40 to 90 Shore A

- Relative Cost: Low

SERVICE TEMPERATURES

- Standard Low Temperature: -40°C / -40°F

- Standard High Temperature: 100°C / 212°F

- Special Compound Low Temperature: -55°C / -67°F

- Special Compound High Temperature: 125°C / 275°F

Nbr Manufacture And suppliers in Dubai, UAE

APPLICATIONS

- Automotive

- Fluid Power

- Electronics

- Hydraulic Fittings

- Valves and Pumps

- Earthmoving & Construction Equipment

- Power Generation

- Instrumentation

- Filtration

- Hydraulic Cylinders

- Plumbing Products

- Petrochemicals

- Chemicals & Fertilizer Plants

- Pharmaceuticals

- Pneumatic Cylinders

- Dairy/Food Processing