MATERIAL OPTIONS

BUTYL RUBBER (IIR)

- BUTYL RUBBER (IIR) has very low permeability rate, good electrical properties,resistance to weathering & ozone.

- Temperature : -40 ℃ to 120 ℃

- Chemical Resistance : Hot Water, Steam, Ozone, Ageing, & Weather Resistance,Silicon Oil & Grease.

POLYTETRAFLUOROETHYLENE (PTFE – TEFLON ®)

- PTFE exhibits outstanding chemical resistance to the harshest media. Non flammable, inert, self lubricating are some of its special properties

- Temperature : -200 ℃ to 260 ℃

- Other Filled grades of PTFE viz. BRONZE, CARBON, GLASS, MOS2 have better mechanical properties than virgin grades.

NATURAL RUBBER (NR)

- NATURAL RUBBER, the oldest rubber available having outstanding resistance to tear, abrasion and cut growth.

- Chemical Resistance : Water Oxidation, Alcohol and Ketones,Moderate Resistance to Acids,Alkalis.

ETHYLENE PROPYLENE RUBBER (EPDM)

- EPDM is a Co-Polymer of Ethylene and Propylene and is mostly used in Brake systems having Glycol based Fluids.

- Temperature : 55 ℃ to 150 ℃

- Chemical Resistance : Hot Water and Steam, Glycol based brake fluids, Organic And Inorganic Acids, Phosphate Ester Based Fluids, Soda, Potassium, Silicon Oil and Grease, Ozone,Aging and Weather resistant.

ACRYLONITRILE BUTADIENE (NBR – NITRILE)

- NITRILE RUBBER (NBR) is the general term for Acrylonitrile Butadiene Rubber. Acrylonitrile content varies from 18 to 50{dc3772c814d55855bfbbe880e92bc799037d5bf67400f818ce2d73f30472dfb3}. Higher the Acrylonitrile content, better the resistance to fuel & oil, and at the same time affecting elasticity & compression set.

- Temperature : -30 ℃ to 100 ℃

- Chemical Resistance : Propane, Butane, Petroleum, Mineral Oil, Grease, Diesel Fuel, Fuel Oils,HFA,HFB,HFC Fluids, Dilute Acids, Alkali, Salt Solutions and Water.

CARBOXYLATED NITRILE (XNBR)

- CARBOXYLATED NITRILE has proven tear and abrasion resistance compared to NBR. It is often used for dynamic applications.

- Temperature : – 30 ℃ to 100 ℃

HYDROGENATED NITRILE (HNBR)

- HNBR compounds exhibits improved heat resistance to the general NBR compounds. They also possess superior mechanical properties particularly high strength.

- Temperature : -40 ℃ to 150 ℃

FLUOROCARBON (FKM – VITON ®)

- FLUOROCARBON (FKM – VITON ®) has excellent resistance to High temperature, Ozone,Oxygen,Mineral Oils Aliphatic and Aromatic Hydrocarbons and many chemicals.

- Temperature : -20 ℃ to 204 ℃

- Chemical Resistance : Mineral Oil, Grease, Non Flammable Hydraulic Fluids, Aliphatic and Aromatic Hydrocarbons Ozone Weathering, Aging, High Vacuum, Steam and Alcohol.

SILICON (VMQ)

- SILICON has best Cold flexibility, Excellent heat resistance, Good Insulating properties,Good Ozone & Weathering resistance, as well being neutral in its properties

- Temperature : -50 ℃ to 232 ℃

- Chemical Resistance : Ozone, Aging, Weathering, Animal & Vegetable oil, Grease, Moderate Resistance to Mineral Oil.

FLUOROSILICONE (FVMQ)

- FLUOROSILICONE (FVMQ) offers improved fuel and oil resistance in comparison to regular Silicon (VMQ), Mechanical and Physical properties being the same

- Temperature : -70 ℃ to 175 ℃

POLYURETHANE (AU)

- OLYURETHANE have the highest Wear resistance, Tensile strength and Elasticity. They have high volume applications in seals for hydraulic cylinders.

- Temperature : -30 ℃ to 80 ℃

- Chemical Resistance : Ozone, Aging, Mineral Oil, Aliphatic Hydrocarbons, Water (upto 50 Degrees C).

STYRENE-BUTADIENE RUBBER (SBR)

- SBR previously known as ‘ BUNA S’ was first produced as a replacement to natural rubber.

- Temperature : -40 ℃ to 105 ℃

- Chemical Resistance : Water, Alcohol, Non-Mineral Oil fluid, Silicon Oil and Grease, Weak Acids

CHLOROPRENE RUBBER (CR – NEOPRENE®)

- CHLOROPRENE popularly known as NEOPRENE exhibits good Ozone, Aging, Chemical,Abrasion & Flex Fatigue Resistance.

- Temperature : -40 ℃ to 120 ℃

- Silicon Oil And Grease, Water and its solvents, Refrigerants,Ammonia & Carbon Dioxide Ozone, Weathering and Aging.

CHLOROSULFONATED POLYETHYLENE (CSM – HYPALON ®)

- CHLORINE in CHLOROSULFONATED POLYETHYLENE imparts resistance to Flame and Mineral Oils and also improves Cold Flexibility

- Temperature : -20 ℃ to 120 ℃

- Oxidising Media, Water, Aging, Grease, Many Acids.

PERFLUORO ELASTOMER (FFKM)

- PERFLUOROELASTOMER (FFKM) exhibits unique resistance even in the harshest environments.It exhibits unbeatable resistance to Acids, Alkalis, Steam, Ketones.

- Temperature : -25 ℃ to 300 ℃

- Aliphatic, Aromatic and Chlorinated Hydrocarbons, Organic And In-Organic Acids, Water, Steam, and Vacuum.

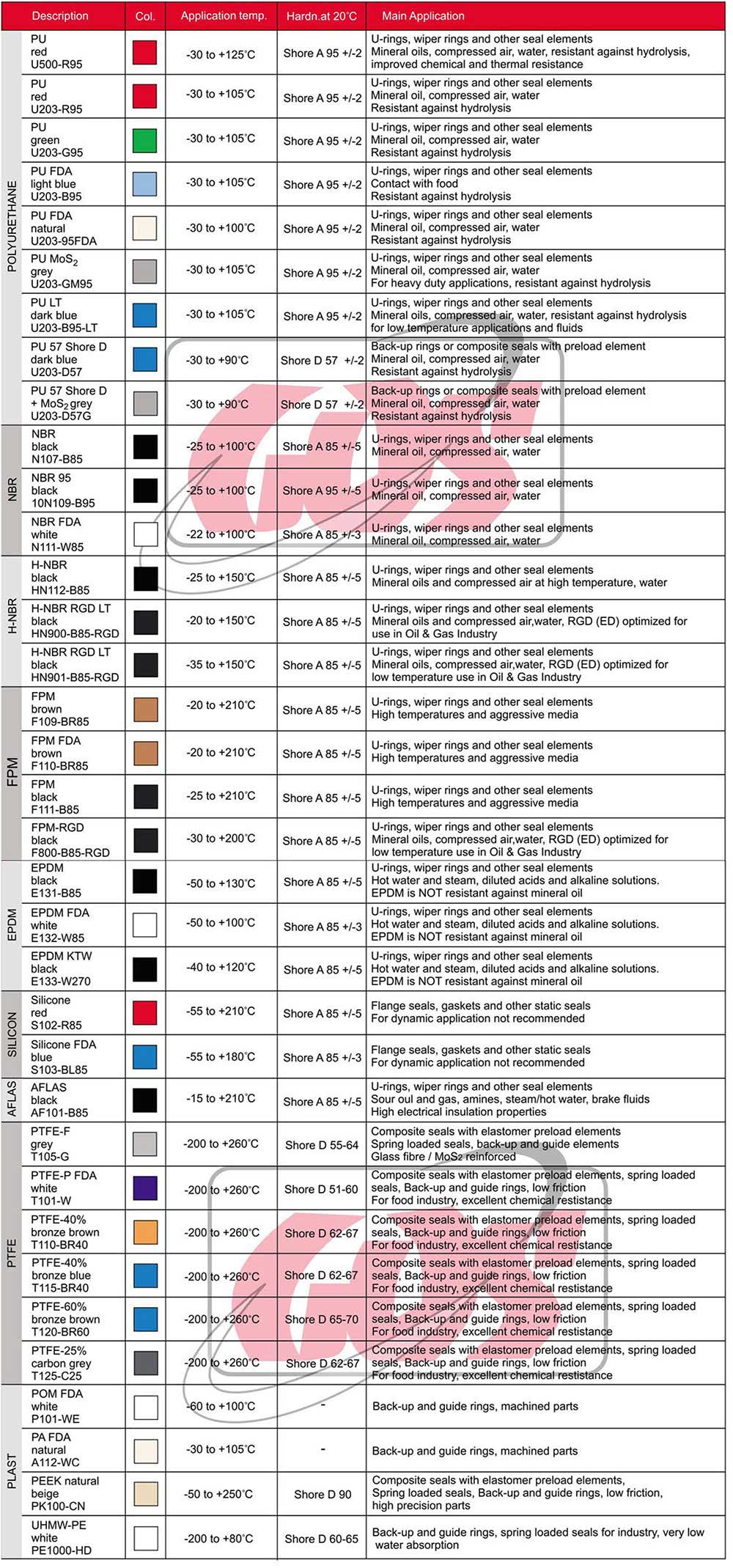

Material Table

The indicated minimum application temperatures are thought as a general guideline because a seals function at lower temperatures is dependent on the kind of the seal.the general application conditions, and on the kind of the surrounding metal parts the seal is in touch with.The indicated upper-temperature limits may be exceeded, but this reduces the service life.Other materials available on request.

In case of doubt you are always welcome to contact our application engineers.